Today’s vertical pump offers flexibility, efficiently and reliably a meet the wide range of system requirements. In order to take advantage of this flexibility, a basic understanding of the pumps main components is required. Of the many components and types of construction available, proper selection depends on factors such as the depth or length of the pump, size and rotative speed, abrasive or corrosive properties of the fluid being pumped, fluid temperature, and the lubricating qualities of the fluid. When unusual conditions are encountered, consultation with a Priest Electric Representative or Engineer is recommended.

COMPONENTS OF A VERTICAL PUMP

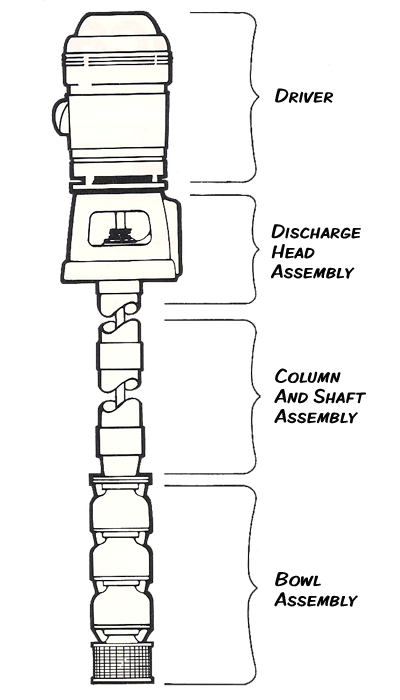

The picture on the left illustrates the four basic components of a typical vertical pump:

- Driver

- Discharge Head Assembly

- Column and Shaft Assembly, and

- Bowl Assembly

DRIVER

The driver provides power to rotate the shaft and impellers. The driver also supports the weight of the shaft and impellers as well as the weight of the unbalanced downward thrust imposed by the pumping action. The electric motor is the driver used in most applications. Other common drivers include internal combustion engines with right angle gear drives or steam turbines.

DISCHARGE HEAD ASSEMBLY

The cast iron or fabricated steel discharge head is supplied in a number of different configurations to meet specific system requirements. The discharge head serves four primary functions:

- Aligns the pump with the driver which eliminates the need for flexible shaft coupling devices;

- Provides external support for the entire pumping unit.

- Directs the flow to the desired direction with above or below the floor discharge.

- Provides either a stuffing box or mechanical shaft seal to seal head from leakage around shaft.

COLUMN AND SHAFT ASSEMBLY

The column and shaft assembly connects the bowl assembly to the discharge head assembly and serves two functions:

- Houses the line shaft bearings provided for shaft radial support; and,

- Channels the fluid vertically from the impellers in the bowl assembly to the discharge head.

The length of the column and shaft assembly depends on system requirements or may be eliminated altogether. The shaft may be either product or oil lubricated.

BOWL ASSEMBLY

The bowl. assembly generally is constructed of standard components stocked in inventory. Bowl size detemines rate of flow while the number of bowls (or stages) determines pressure or head. Impellers may be of either the enclosed or semi-open design.

The type of suction connection can be varies to adapt to different piping systems and applications. Suction connections may be fitted with strainers for well systems or open collection basins, threaded or flanged for rigid connection to piping systems, or with bell-mouth inlets for sump or barrel systems.

Priest Electric is the leader in new vertical pump sales and repair, we can help you configure your pump for your specific requirements.

Contact us today by calling

208-459-6351

or Online