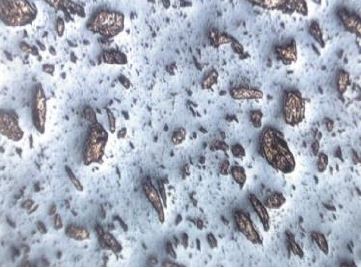

The advanced Silicon Carbide (SiC) sealing face material AST uses provides for longer life and is more durable than other SiC materials.

Graphite Loaded Alpha Sintered Silicon Carbide Photo Provided by Morgan Advanced Materials

Graphite Loaded Alpha Sintered Silicon Carbide The free graphite improves lubricity for greater dry run survivability and better thermal shock resistance than conventional sintered materials. Increased PV (pressure-velocity) capability between hardface mating pairs, due to the presence of graphite, makes the silicon carbide we use (PGS-100) the best solution for all types of hardface pair sealing applications.

Material Advantage #1: Graphite Inclusions The graphite inclusions act as sponges for process fluid. If the mechanical seal operates dry for short durations, the graphite inclusions can release liquid between the seal faces to help lubricate and prolong seal life.

Material Advantage #2: Thermal Shock Resistance The graphite inclusions act as shock absorbers when material is pushed to limits. Other sintered silicon carbides may fracture at lesser shock levels.

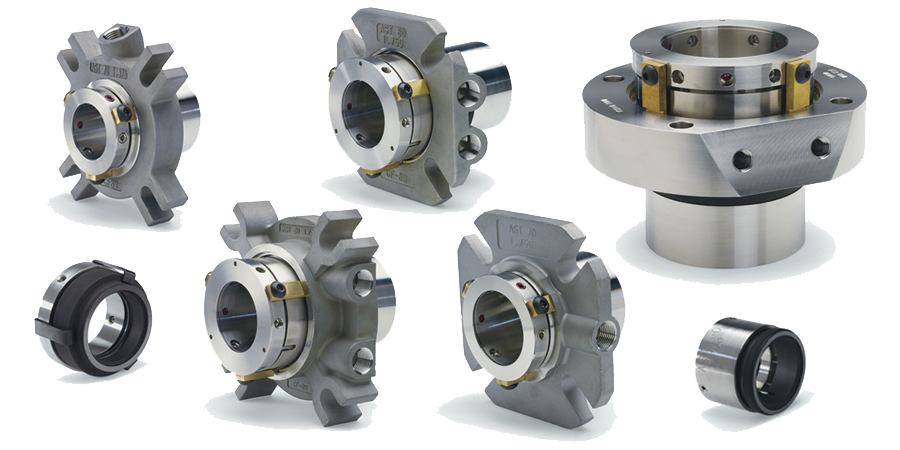

Call Priest Electric for more details or to order AST Mechanical Seals.

1.208.459.6351