Set Up of Plan 52 Reservoirs Seal Pots

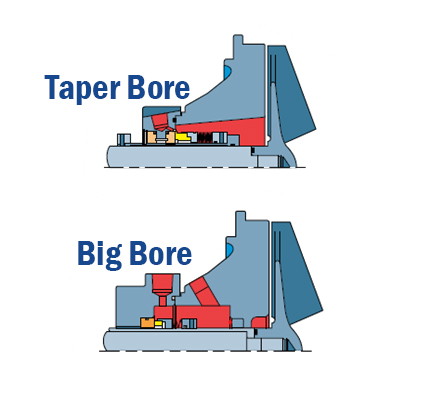

Piping Plan 52 Set Up (Graphics Courtesy of Hydraulic Institute, www.pumps.org) Dual mechanical seal with reservoirs can be used with good effect in implementing Plan 52 to provide buffer fluid resulting in no direct leakage of process fluid to the atmosphere. Circulation between the reservoir and outer seal is maintained by tangential flow porting [...]