Mechanical seals are extremely important in a machine and/or pump. The seals prevent leakage which can cause damage to a pump. There are primary and secondary seals which consist of other types of seals. Priest Electric is a great source to find out which seal is correct for your pump.

Mechanical seals are extremely important in a machine and/or pump. The seals prevent leakage which can cause damage to a pump. There are primary and secondary seals which consist of other types of seals. Priest Electric is a great source to find out which seal is correct for your pump.

The primary mechanical seal consists of a stationary seal and a rotating seal. These seals are extremely flat and “rub” together, lapped within two light bands. Together these seals prevent leakage because of their flatness and are 85 light bands to one thousandth of an inch. There may be some very minor leakage between these faces however it appears as a vapor.

The secondary seal is the rotating face and is sealed to the shaft by an elastomer, along with the stationary face which is sealed to the stuffing box, gland by a gasket, or another elastomer. The faces are held together by a combination of spring pressure and hydraulic force created by the fluid that is being sealed. As long as the faces are held together, leakage should not occur. All shaft movement must take place through the elastomer. If the shaft cannot move easily through the elastomer, the faces can be pulled open, and leakage can occur. Once opened, dirt or abrasives can penetrate between the faces. If the rotating components of a mechanical seal rotate against each without some form of lubrication, they would soon wear out due to face friction and generating heat.

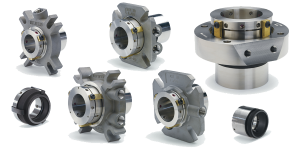

The different types of Mechanical Seals:

Rotating seal, stationary seal, unbalanced seal, balanced seal, and the horizontally or vertically mounted seal. The rotating seal is the most common and is used when the component that holds the springs rotates with the shaft. In contrast the stationary seal is used when the component that holds the springs is held stationary in the gland plate.

Where the stuffing box pressure creates a wedge shaped force attempting to push the faces apart and the spring pressure tends to push the faces together, an unbalanced seal is used. A balanced seal is used where the seal is engineered with a “step” which allows greater stuffing box pressure to close rather than open the faces, which reduces the face load, reducing the need for spring pressure.

The quality and make of mechanical seals is important. Applying the correct seal for the correct function is extremely important. Priest Electric is one of the best in the business and will provide the knowledge you need to make sure your pump has the correct mechanical seals.

Leave A Comment