How to recognize potential mechanical seal failure: wear groove on seal face

Get into a root cause/corrective action mode when you start noticing a wear groove on the seal face in order to prevent potential mechanical seal failure.

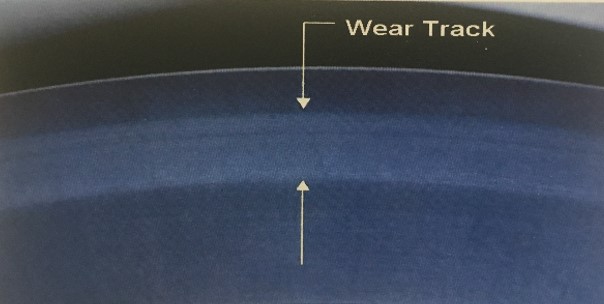

Normal Wear Pattern on Seal Face

Deep Wear Groove on Seal Face

Common Root Causes:

Inadequate Lubrication.

Potential Corrective Action:

- Proper start-up procedure (ensure pump does not start dry, valves are open, seal chamber is flooded, air is vented).

- Use proper seal flush plan.

Abrasive (or corrosive) Materials Present in the Process Fluid.

Potential Corrective Action:

- Use hard faces such as silicon carbide or tungsten carbide.

- Use proper seal flush plan.

Scale or Crystallization build-up on the Seal Face.

Potential Corrective Action:

- Use a dual cartridge seal with a proper piping plan.

- Use hard faces such as silicon carbide or tungsten carbide.

Call Priest Electric to speak with a mechanical seal specialist if you have any questions or concerns. 208-459-6351