Best Efficiency Point (B.E.P)

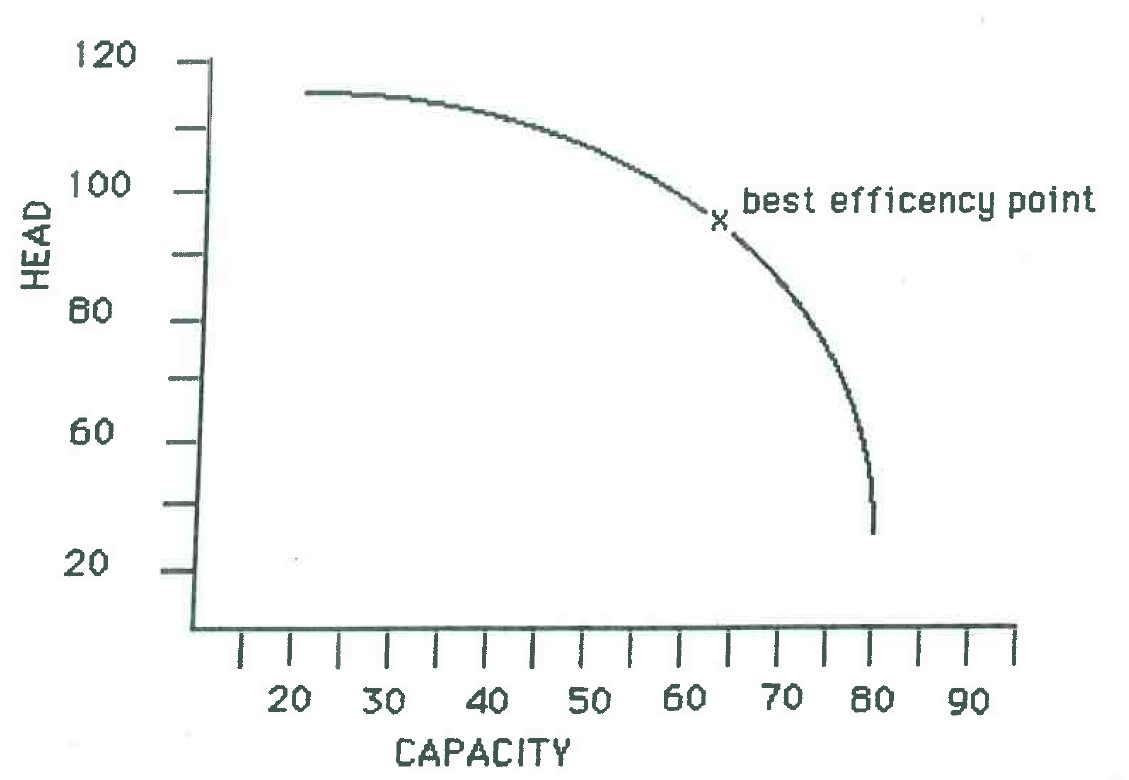

We hear a lot about operating pumps at the best efficiency point from pump manufacturers and engineers. It is noted on most pump curve drawings and is common terminology implementing or troubleshooting pump installations.

The Best Efficiency Point (B.E.P.) is described as the point where we have the least amount of shaft deflection and the power input is closest to the power output. In other words, the shaft is not bending and we are using the least amount of power for the job the pump is doing.

The best efficiency point is usually somewhere between 80% and 85% of the pumps shut off hear, which means we need to look at the pump curve to get an exact number.

The results of incorrect application, design problems, or system changes affecting B.E.P. can include bearing damage, mechanical seal failure, rubbing, or wear all around the rotating part, and one spot on the stationary part. All this results in premature failure and higher maintenance costs. It also increases power consumption, resulting in higher power costs.