What Is The Difference Between Single and Dual Mechanical Seals?

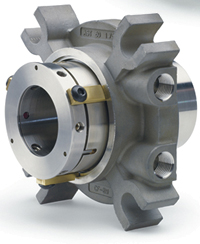

Single Cartridge Seal – AST

What Is A Single Mechanical Seal?

A single mechanical seal consists of two very flat seal faces that are forced together by a spring and slide against one another. Between these two faces is a thin fluid film generated by the process fluid or pumped product. This fluid film (typically gap of 1 micron or 75 times narrower than a human hair), lubricates and cools the seal. An absence of this thin fluid film (pump running dry or product flashing) results in frictional heat and ultimately the destruction of the mechanical seal.

The sealed fluid typically enters the gap between the seal faces as a liquid. As it migrates across the seal faces from the high-pressure side to the atmosphere, its pressure drops, and temperature rises. The liquid may vaporize so there may be no visible liquid leakage. A correctly specified seal operating properly will typically meet VOC emissions standards.

A single mechanical seal is typically used when the process fluid that is pumped presents little to no risk to the environment.

Dual Cartridge Seal – AST

What Is A Dual Mechanical Seal?

A dual mechanical seal consists of two seals arranged in a series. The inboard seal keeps the product contained within the pump housing. The outboard seal prevents the barrier or buffer liquid from getting into the atmosphere.

A double hydraulically balanced dual cartridge seal can be used in any of three different arrangements.

- Double Seal: With barrier fluid pressure higher than product pressure the seal prevents leakage of toxic or hazardous fluids into the environment. The barrier fluid provides lubrication to seal gasses and non-lubricating fluids.

- Tandem Seal: By using a buffer fluid with pressure to lower than process, the seal can reduce the pressure differential across a single set of seal faces.

- Spare Seal: With unpressurized buffer fluid the outboard seal operates “at idle” as a standby seal. If the inboard seal fails, the outboard seal provides primary protection, eliminating unscheduled shutdown of batch processes.

Double mechanical seals are typically used in the following circumstances:

- If the fluid and its vapors are hazardous to the operator or environment and must be contained

- When aggressive media are used at high pressures or temperatures

- For various polymerizing, or sticky media.