Single Spring Seal vs. Component Seal vs. Cartridge Seal

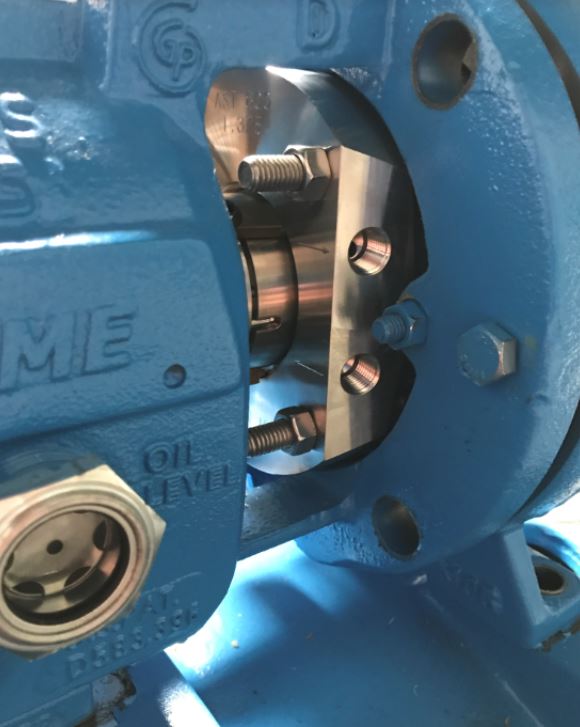

Single Spring Seal vs. Component Seal vs. Cartridge Seal GOOD Single Spring Seal BETTER Component Seal BEST Cartridge Seal Positive Low initial cost Good alternative to packing Positive Inexpensive initial cost Multiple springs for even loading on seal faces Springs outside of process fluid [...]